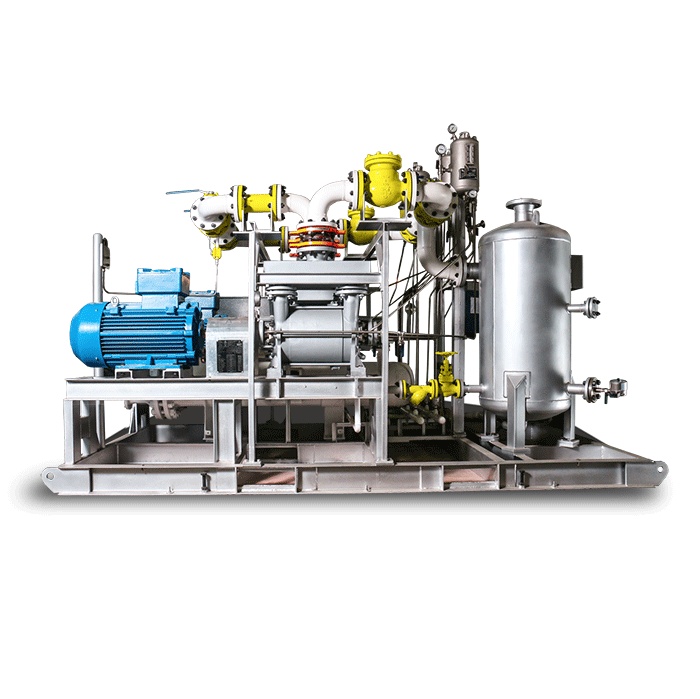

Description

ApplicationsThe engineered liquid ring vacuum pump packages are used in all industries. Below, you can find a list of some example applications. • Vacuum system for distillation towers for crude oil and other products • Vacuum generation and vapor recovery in vessels under vacuum • De-aeration and vacuum generation systems • MEG recovery in MEG reclamation units • Replacing steam ejectors • De-aeration and vacuum generation in condensers and steam turbines in power plants, de-aeration of circulated water • Vacuum generation in reactors |

Specification• In compliance with the requirements and specifications of the project however stringent • In compliance with the standards used in oil, gas and petrochemical industries (API, ASME, …) • Providing engineering documentation based on VPIS (Vendor Print Index Schedule) including drawings, calculation books, fabrication and inspection procedures, weld books (WPS, PQR, WQT), PFD, P&ID and VDB (Vendor Data Book). • Conducting inspections and tests during manufacturing and at final stage before delivery based on approved ITP (Inspection and Test Plan). These tests include material certification, dynamic balancing of rotating parts, hydrostatic testing, NDT tests such as PT, RT or MT, performance and mechanical running tests, vibration and noise tests, … • Project control based on WBS (Work Breakdown Structure) and project time schedule and submitting progress reports (monthly or bi-weekly) to the client Performance Range• Capacity from 500 to 20000 m3/hr • Vacuum pressure up to 10 mbar a (using ejectors) • Vacuum pressure up to 1 mbar a (using vacuum boosters) • Power consumption from 15 to 750 kW |

|

|

|