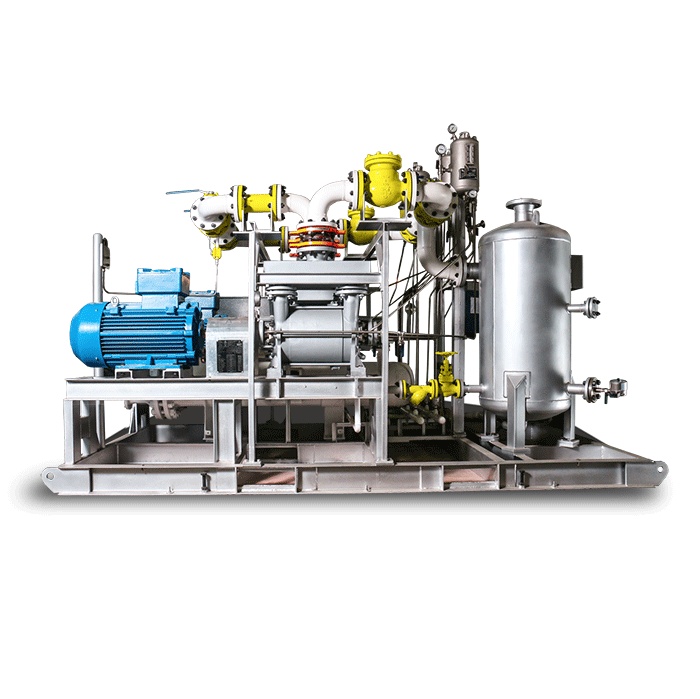

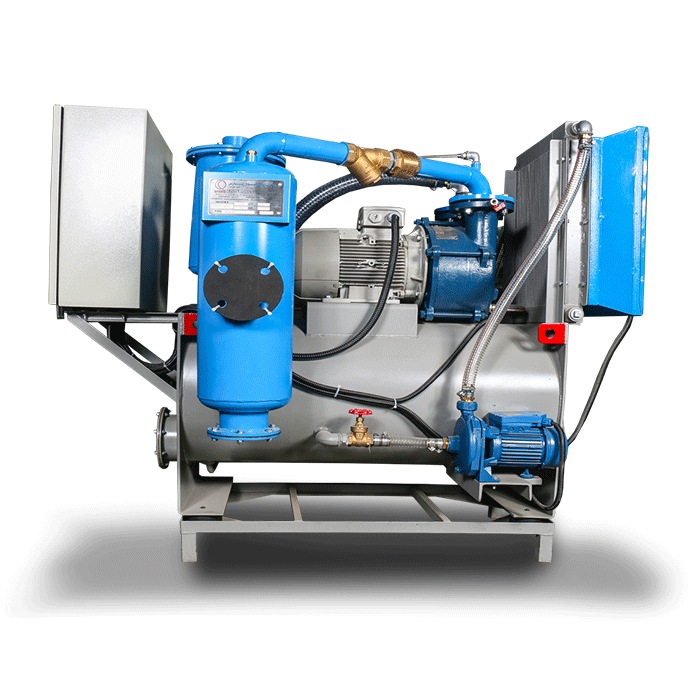

Oil, gas and petrochemical industries are one of the main industries in our country and there are quite a lot of applications and processes requiring compression and conveyance of compressible fluids. Using competent and well educated engineering staff and a wide range of products to offer, Pars Vacuum Industries is one the first choices for these industries to choose.

We, at Pars Vacuum Industries, know too well the importance of longevity of lifetime, durability of design and reliability of the products as the key difference making factors in these industries. With this in mind, we offer the best solutions based on the specific customer needs and these industries specific standards (API, IPS, ASME …)

Here is a brief list of applications in these industries where our products are being used

- Distillation and filtration of products

- Vacuum generation and de-aeration in different processes

- Furfural oil production units

- Compression and conveyance of process gases

- Instrument and plant air solutions

- Vapor recovery units working under vacuum

- MEG reclamation units

- Furnace aeration for flue gas desulfurization

- Flare gas recovery system for recovering flare gas and hydrocarbon by-products

- Aeration application in waste water treatment in refineries/plants